|

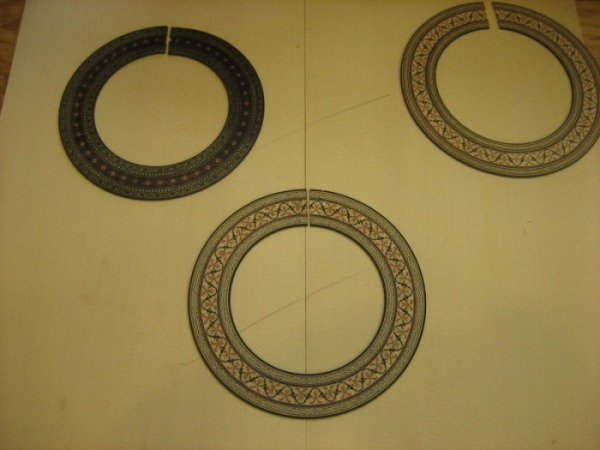

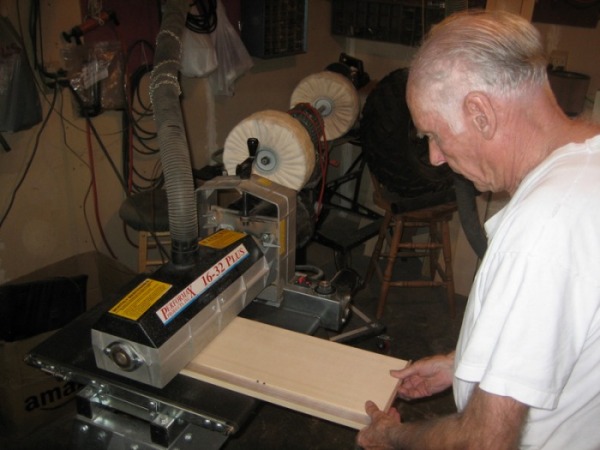

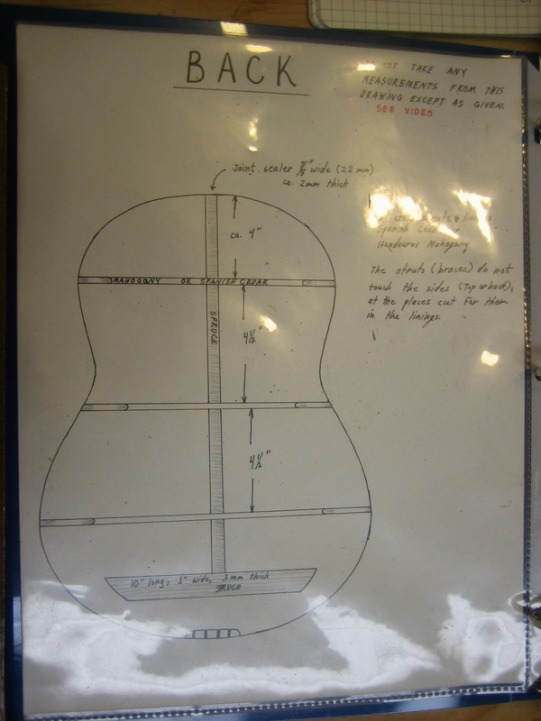

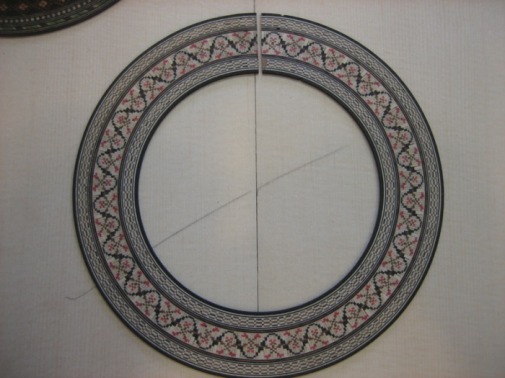

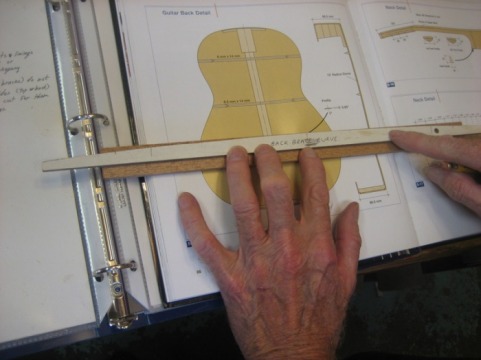

Work Day #1 - September 20th, 2008 (3 hrs) The stripes are amazing.. Then we looked at rosette's, the fingerboard, and head plate. We were trying to get an idea of what colors we could play with and what would look good.  Depending on what we decide on for a head plate, my top pick for the rosette is this one. It picks up the light color of the top and has a real classic look. Above is a picture of Georg Karl Hannabach...he is the master guitar builder from Germany who taught my dad how to build guitars. He came to my dad's house in 1997 and built a guitar w/ him while he was there...a pretty cool opportunity! Then we needed to make sure the edges were square and ready for glue. There are several different ways to do this. One is on a belt sander (w/ 80 grit paper), and the other we used was with a piece of glass w/ sandpaper (various grits 80-120) glued to it as shown below. To check how the edges match up, simply hold the pieces together toward a light source...in our case, the shop window. Usually you would sand the pieces sandwiched together...but you can also sand them separately. Now we need to get set up to glue the two halves together. The two halves are from a thick piece that has been split down the middle, then you fold the pieces out so you have a mirror image of the grain. We let the glue dry for about an hour then worked on removing the excess glue with a cabinet scraper. The scraper is a piece of steel anywhere from .4mm - .7mm thick and about 4-5 inches long and 2-3 inches high w/ a sharp edge. The edge is applied by filing the square edge at a 45 degee angle then burnishing (w/a steel burnisher) the edge to 90 degrees. And when the edge gets dull, simply grind it flat and make a new edge. We also followed up the scraping w/ some 100 grit paper on a sanding block. Once the glue was sanded down and the seam looked as though it wasn't even a seam, we were ready to trace the pattern onto the wood. You want to make sure and leave at least 1/4 inch between the pattern and the edge of the wood. Dad has a plexiglass pattern of one side of the guitar, so you trace the first half, flip it over and trace the second. We traced the pattern onto both sides of the back. And now we are ready to move on to the top...where the exact same steps were taken - thinning the wood, squaring the edges, gluing, and removing the excess glue. Work Day #2 - October 7th, 2008 (4 hrs) Ok...on to the back. The first piece to be applied is a vertical brace that runs along the seam. The brace is made from two pieces of Spanish cedar glued together. The vertical brace should have the grain running perpendicular to the grain of the back. This brace is 3mm thick by about 30mm wide and the length varies. But it should start about 1 inch from the top of the back to about 2-3 inches from the bottom.  While the vertical brace dried, we moved on to the horizontal braces. For this guitar, mahogany will be used. The horizontal braces range from 6mm thick to 7mm thick. Brace 1 (starting from the top of the back) is 6mm thick and about 14mm tall and will be placed approx 4 inches from the top. Brace 2 is 6.5mm thick, 14mm tall and will be 4.5 inches below brace 1. Finally, brace 3 is 7mm thick, 14mm tall and will be 4.5 inches below brace 2. From what my dad says, it seems like the bracing is largely subjective. Some guys will do 5mm thick braces that are taller...like 18mm. Others will use 6mm thick bracing on all 3. And the type of wood used varies as well. Dad suggested the mahogany as it is a nice hard wood and the pieces we used are aged enough to have the strength we want.  After the 3 braces were cut to size, we penciled in the curve from a pre-made template. The curve added to the braces when glued to the back, gives the back its delicate curve. The curve is equivalent to a circle made with a 20' radius...so it's easy to see how gentle the curve really is. Now with the vertical brace glued we removed the clamps and started shaping it. Here is a before and after look: The finished brace will have a slight curve to it but you don't what to thin the edge flush w/ the back, you want to leave a .5mm edge. With the vertical brace shaped, it's time to cut the grooves for the horizontal braces.     The finished groove should allow the horizontal brace to easily slide down and contact the back.   With the glue applied to the curved side of the brace we dropped it into the groove. Make sure to line up the ends w/ the marks at the edge of the back made when marking the lines to cut the groove.  We used thin pieces of wood between the clamps and the back as tightening the clamps draws the back around the curve of the horizontal braces so the pieces need to be flexible and we wanted the clamps to not rest directly on the outside of the back.  Before gluing the center brace, we prepared a brace that Hannabach uses to prevent splitting from the bottom of the back. This piece is 2mm thick and varies in length. Ours is approx. 9" wide and 1.5" wide. The piece started as a rectangle, and we added a bit of a curve to each end...just for decoration. We also tapered the edges slightly as seen in the picture above.  And that's where we ended on work day #2. After the glue set up for an hour or so, Dad removed the clamps and set it aside to be finished later.

1 Comment

Tom Bates

9/21/2008 02:19:46 pm

Erich, this is great! It'll make a great record of your project. I'll bet Marlo is pretty proud of this too.

Reply

Leave a Reply. |

|